Landscape Fabric, Geotexiles, Geogrid

Stabilize Your Terrain With Geosynthetics

Kleener Image carries a variety of geosynthetics for your construction projects. Stop by or call about our selection of geogrids, non‐woven geotextiles, and more!

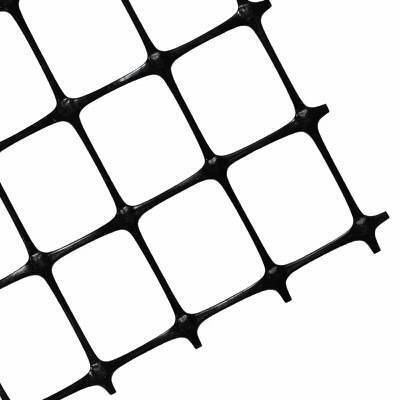

Geogrid

Kleener Image offers a full line of punched and drawn polypropylene geogrids. Geogrids can be used in base reinforcement applications to reduce aggregate base, extend roadway life, and reduce construction timelines. Punched and drawn geogrids offer superior junction strength and efficiency, thus achieving a more reliable aggregate interlock and stabilizing subbase sections more efficiently.

- SG150 ‐ 3 Series 4’ x 50’

- SG200 ‐ 5 Series 6.25’ x 288’

- GSRW 71215 ‐ 7 Series 12’ x 150’

- Type 1 Grid 13.1’ x 246’

- Type 2 Grid 13.1’ x 164’

Commonly Asked Questions About Geogrid

How deep should the geogrid be?

How is geogrid used as a soil reinforcement?

Geotextiles

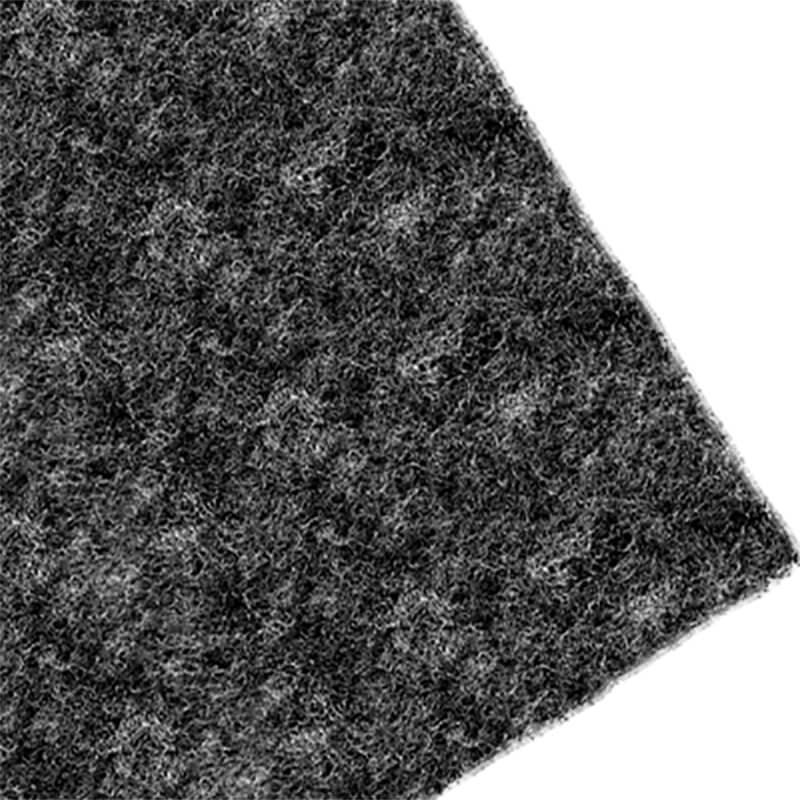

Non‐Woven Geotexiles

These heavier-weight fabrics are designed for applications where higher strength, stability, and performance are necessary. This fabric is one of the most commonly used geotextiles for road stabilization, ground stabilization, and aggregate separation. Made of polypropylene, the geotextile is non-biodegradable and UV resistant as well as being resistant to commonly encountered soil chemicals, mildew, and insects. Polypropylene is stable within a pH range of 2 to 13, making it one of the most stable polymers available for geotextiles today. This fabric is also useful for filtration purposes as it restricts the movement of soil particles while allowing water to pass through. The fabric is also useful for shoreline restoration along with erosion control as it helps hold the soil in place when used under gabions.

STRONGHOLD NW6

STRONGHOLD NW6 is ideal for applications requiring ground stabilization, aggregate separation, and soil reinforcement. These fabrics feature a needle-punched exterior that aids filtration applications. These geotextiles are ideal for drainage, asphalt overlay, and various other filtration requirements. The lightweight fabrics are slightly lower in strength but have increased permeability levels making them a great option for use in both street and French drains. Weighs 6.0 oz

- Nonwoven – 6 Ounce 12.5’ x 360’ & 15’ x 300’

STRONGHOLD NW8

These medium-strength geotextiles are ideal for long-term applications that require extra strength, high UV resistance, and high rotting prevention. Weighs 8.0 oz

- Nonwoven – 8 Ounce 15’ x 300’

Stabilization Fabric

A fabric that is used to stabilize roadways, airport runways, or any surface requiring a special foundation over unstable ground. The stabilization fabric allows the instation of a drainage layer immediately above the fabric.

- 12.5’ x 27’

- 12.5’ x 54’

- 12.5’ x 432’ 200lb

- 15’ x 360’ 315lb

Landscape Fabric

The original landscape fabric that started it all is easy to cut and install. This particular fabric starts out with a woven piece of fabric like the ground cover, and then the non-woven (fuzzy) material is added. The non-woven fabric’s only function is to increase water permeability. Heat sealing (melting) the edges prevents the fabric from fraying or unraveling. Since the fibers are synthetic and not natural, the material resists rotting and degradation. The black woven needle-punched fabric offers excellent strength and toughness with a high degree of UV resistance. Air and water flow through easily while weed growth is severely restricted. The black color prevents light penetration and the needle punching method of fabrication provides stability on slopes. Color stripes 12″ apart allow for easy plant spacing and alignment.

In most applications, the fabric should be placed fuzzy side down. This is especially true if weed control and soil stabilization are the primary goals. If mulch is to be used over the top of the fabric, place the fuzzy side up to help “hold” onto the mulch.

Professional Polyspun 3 Ounce

- 3’ x 50’

- 3’ x 100’

- 3’ x 300’

- 4’ x 100’

- 4’ x 300

- 6’ x 300’

Woven Needle Punch – 5 Ounce

- 3’ x 250’

- 4’ x 250’

- 6’ x 250’

- 8’ x 250’

Contact Kleener Image Today

Reach out to us with any questions or to purchase products and services by calling us at (515) 556-8673 or by visiting our location in Grimes.

Contact Kleener Image